ALL IN THE PREPARATION

NewGen Direct uses expertly developed freeze drying processes, which make it possible to capture 100% of the nutritional benefits and flavours of our raw wholefood fruits and veggies. Freeze drying is the ultimate and most expensive process to dehydrate these types of foods.

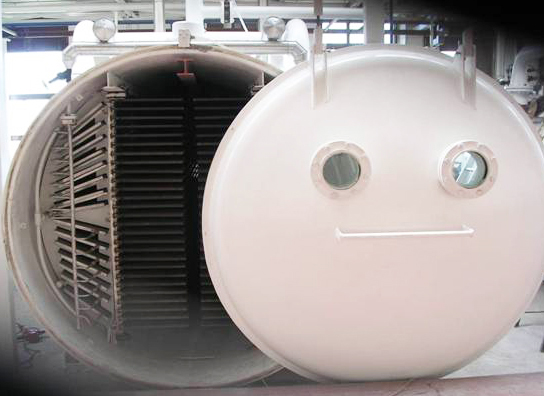

During freeze drying, the frozen raw wholefoods are placed in a refrigerated vacuum system for between 1 to 3 days and are gently dehydrated before they can thaw. Under these conditions, the ice turns directly into water vapor without passing through the liquid phase. Unlike other drying methods, the freeze-drying process allows the retention of the full nutritional value of these foods to remain intact, including their colour, shape, taste, naturally occurring enzymes and the integrity of the cell structures.

WHY DO SOME COMPANIES USE CHEAPER DRYING PROCESSES?

When companies produce low cost products, freeze-drying fruits and vegetables is cost prohibitive, as the ingredients themselves often work out around twice the price when compared to the standard drying process. Remember, even products which are expensive to the consumer can be cheaply made. Please see our article on Price Comparisons. With attractive labels and clever marketing, cheap products can look just as impressive as high quality products, but they are worlds apart when it comes to the benefits that they offer.

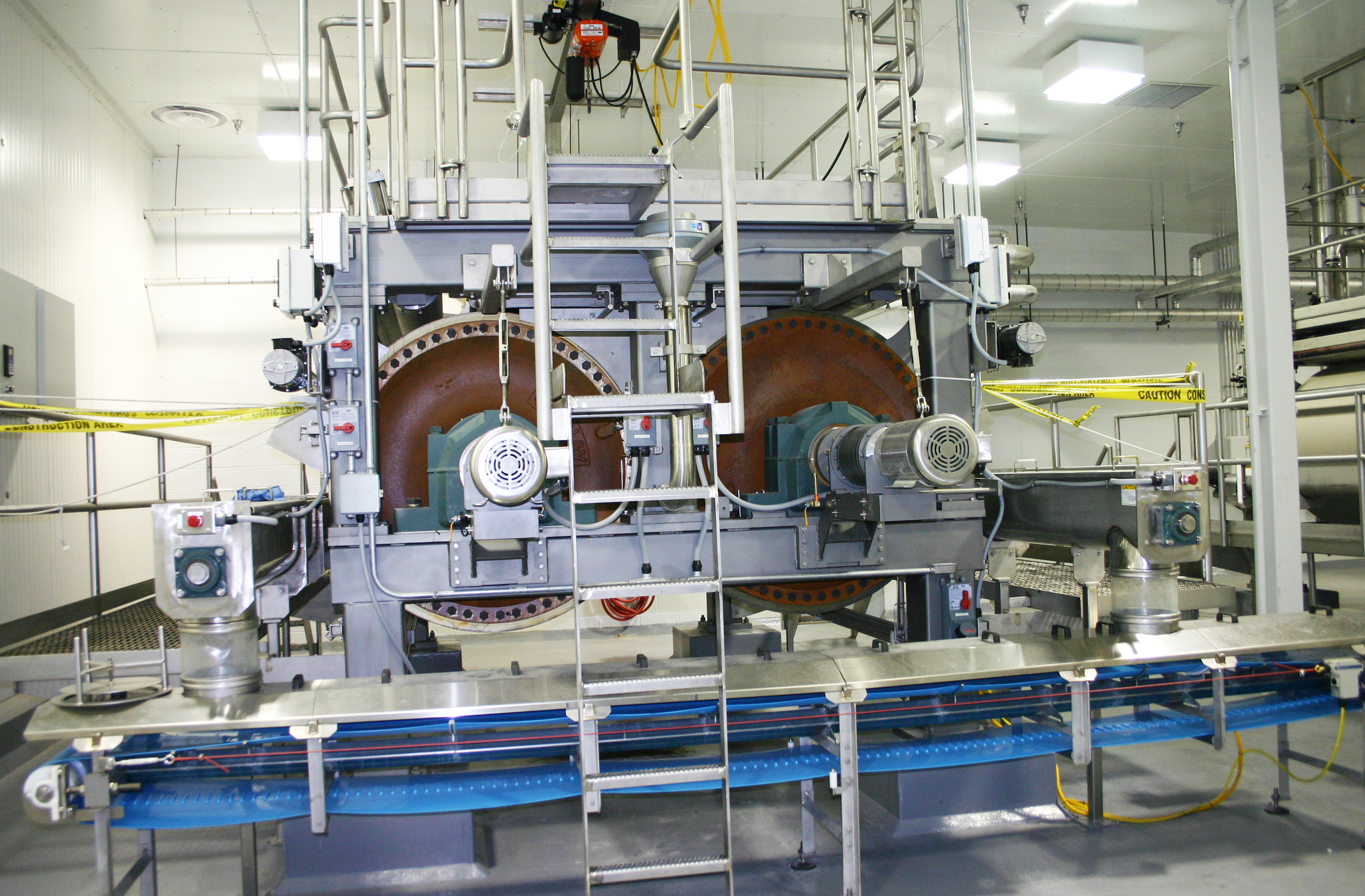

One of the most common drying processes used by companies to dry their fruits and vegetables, uses a flame furnace to dry the ingredients. The intensity of heat destroys approximately 40% of the vitamins and denatures the enzymes. This particular machinery also requires the fruit and veggie ingredients to be mixed with very high levels of maltodextrin, which usually is mixed in at a ratio of 60% ingredient to 40% maltodexrin.

WHY DO SOME COMPANIES USE CHEAPER DRYING

Apparently, some companies even request a ratio of 10% ingredient to 90% maltodextrin to reduce their costs. When using the much more expensive drying process, freeze-drying, maltodextrin is generally not needed as there is no heat used and 100% of the nutrients, taste, flavour and enzymes are retained. Maltodextrin may be sprinkled on the trays in very small amounts in a freeze-drier when drying very sticky ingredients like Goji Berries and Pomegranates, however most ingredients do not require it. Certified organic companies do not use genetically modified maltodextrin, as we are regulated not to use any genetically modified substances.

If we take a blueberry as an example, a company using certified organic bluberries which are freeze-dried will be 3 to 4 times more expensive compared to a conventionally farmed blueberry which is Drum Dried with heat.

At NewGen Direct, we take great pride in the lengths that we go to, using only the finest quality ingredients, the very best manufacturing practices, advanced formulations and cutting-edge science. Our certified organic freeze dried ingredients are the best money can buy, but because we do not apply typical industry mark ups to our product, we often undercut companies who use conventially farmed ingredients dried by much cheaper methods.